Included in this short film is an interview with Sandro Albaladejo, great great grandson of our founder and the company’s current Sales Director.

Carmina is a shoemaking company that comes from a long line of shoemakers that began in 1866 in the city of Inca, in Mallorca, Spain. My great, great grandfather Matias Pujadas founded the company, my parents formed the Carmina philosophy, and my siblings and I are in charge of the brand’s internal workings. For a few years now, the Chelsea boot has become one of our star models in the men’s collection (...) Once we have cut the pieces, we have a specialized molding process, where we manage to give the leather the curves that make our Chelsea boots so special.

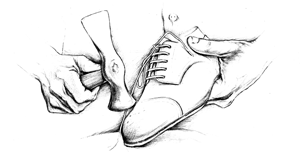

After discussing the process with designer Enrique Simonet and master clicker José Vicens, who helps to ensure we only use completely clean leather free of blemishes and imperfections, Nick arrived at our specialized lasting area.

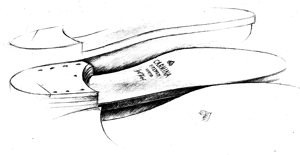

Our footwear is lasted better than any others in the industry because we shape it before the leather is stretched over one of our thirty different lasts. This special step, combined with the sheer variety of lasts available, enables us to sell the best fitting shoes a customer can buy.

To read more about the production, stitching, and finishing that makes our footwear unique, read the