Carmina account required to add an item to your wishlist

Create account now

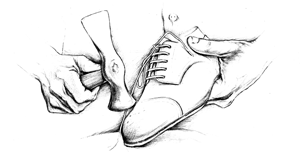

9 · DE-WELTING OR EDGE EVENING

The excess of the soles is trimmed to create an even edge

DISCOVER IT ON VIDEO

The next step is evening out the edges of the soles in preparation for the heel attachment. The excess left on the sides of the soles is trimmed down before attaching the heel. We will then cut into the sole to create a flap in which we will create the closed channel stitching.

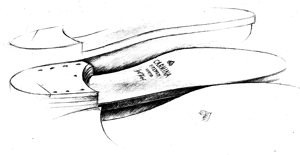

Our heels are also made in-house by our artisans, this is done with several layers of calf leather laid one upon the other to obtain a compact body that will never crack or shift. With this method, we can ensure every heel is customised to fit the different lasts perfectly.

The sole is then stitched to the welt piercing all the layers to create a compact stitch. The stitch line is then encased by pressing the flap to create a closed stitch sole.

EXPLORE OUR BESTSELLING MODELS

10

PAINTING AND SHINE

Finishing the edges and soles